Solvent Extraction Plants

Price 2500000 INR/ Unit

Solvent Extraction Plants Specification

- Product Type

- Solvent Extraction Plants

- General Use

- For Extraction Of Oil

- Material

- Other

- Capacity

- 10 to 1000 Ton/day

- Type

- Extractor

- Weight (kg)

- Up to 50000 Kilograms (kg)

- Computerized

- Yes

- Automatic

- Yes

- Voltage

- 220-440 Volt (v)

- Feature

- Corrosion Resistance, High durability, Efficient Extraction, Energy Saving

- Color

- Green / Customized

Solvent Extraction Plants Trade Information

- Minimum Order Quantity

- 1 Plant

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 1 Plant Per Month

- Delivery Time

- 10 Months

- Main Domestic Market

- All India

About Solvent Extraction Plants

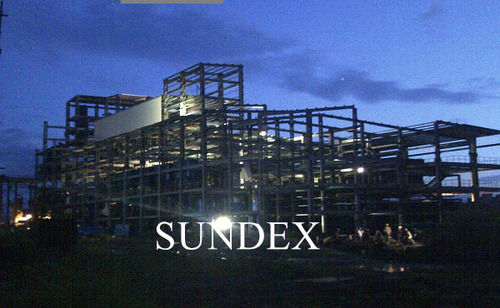

Solvent Extraction Plants

Solvent Extraction, as the name suggests is a process to extract the oil from oil bearing materials by means of Solvent. Solvent Extraction Plants offered by sundex are versatile in operation. Any oil bearing material after subjecting it to recommended preparation can be extracted in the same Solvent Extraction Plant. Special preparatory equipments are recommended to suit individual characteristics of raw materials. Sundexs proven design is simple, robust, operator friendly flexible for easy change over of the process material and with inbuilt safety features. Sundex plants have been operating with good results for almost two decades and more.

Specifications:

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Automatic Grade: Automatic

Product details

|

Automation Grade |

Automatic |

|

Installation Services |

Yes |

Advanced Extraction Technology

Our solvent extraction plants employ state-of-the-art technology featuring efficient extractors and heavy-duty electrical motors. The process ensures high oil recovery efficiency and optimizes energy consumption, with a corrosion-resistant build that supports intense operations. Designed for green operation and customizable to specific plant sizes, these systems safely maintain low noise and include overload protection for uninterrupted performance.

Custom Solutions for Varied Oilseeds

Whether you need to process soybean, sunflower, rapeseed, or cottonseed, our facilities are meticulously tailored to meet your specific requirements. The use of hexane or customer-preferred solvents guarantees optimal extraction for all raw materials. Customizable capacities and colored finishes further provide flexibility for different operational needs, making these extraction plants ideal for diverse industrial contexts.

User-Friendly Design & Maintenance

Our plants are built for ease of operation and maintenance. With automatic operation, computerized PLC control system, and features like explosion-proof design, routine maintenance is minimal and straightforward. After-sales service is readily available, ensuring ongoing support to keep your plant running efficiently. Operators benefit from low noise, high durability, and easy monitoring of procedures.

FAQs of Solvent Extraction Plants:

Q: How do the Solvent Extraction Plants ensure oil recovery efficiency up to 99%?

A: The plants utilize optimized extractor designs, carefully controlled solvent usage, and precision temperature regulation (ambient to 60C) to achieve up to 99% oil recovery from processed oilseeds such as soybean, sunflower, rapeseed, and cottonseed.Q: What is the process for installing these solvent extraction plants on-site?

A: Installation is carried out on-site by our expert team, following detailed pre-assessment and customization of plant size and configuration according to user requirements. All setup procedures prioritize safety, efficiency, and seamless integration into existing operations.Q: When is preventive maintenance required for these plants, and what does it involve?

A: Preventive maintenance is minimal, owing to the plants robust, low-maintenance design. Regular inspections of the extractor, motor, and PLC system are usually recommended, alongside routine checks for corrosion resistance and safety features like overload protection.Q: Where can these solvent extraction plants be deployed?

A: These plants are suitable for oil extraction facilities, refineries, and agro-industrial complexes across India and worldwide. Each plants dimensions are tailored to fit the customers site requirements and production capacity, ranging from 10 to 1000 tons per day.Q: What types of raw materials can be processed in this extractor system?

A: Our solvent extraction plants efficiently process a wide variety of oilseeds including soybean, sunflower, rapeseed, and cottonseed, ensuring effective extraction regardless of specific seed type or mix.Q: How does the automatic, PLC-based control system benefit plant operation?

A: The PLC-based control system automates extraction, enhances operational safety, simplifies monitoring, and enables precision control. This reduces reliance on manual intervention, increases efficiency, and makes the process user-friendly.Q: What safety features are integrated into the design of these extraction plants?

A: Safety is prioritized with explosion-proof engineering, overload protection, and robust construction. These features together minimize risks associated with solvent use and help ensure safe, uninterrupted operation for both staff and equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solvent Extraction Plant Category

Sunflower Seed Solvent Extraction Plant

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Product Type : Sunflower Seed Solvent Extraction Plant

Voltage : 220440 Volt (v)

General Use : For Extraction Of Oil

Expander And Enhancer Systems

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Product Type : Expander And Enhancer Systems

Voltage : 220440 Volt (v)

Cotton Seed Solvent Extraction Plant

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Product Type : Cotton Seed Solvent Extraction Plant

Voltage : 220440 Volt (v)

General Use : For Extraction Of Oil

Canola Solvent Extraction Plant

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Product Type : Canola Solvent Extraction Plant

Voltage : 220440 Volt (v)

General Use : For Extraction Of Oil

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese